+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Choosing the right bucket teeth is crucial for maximizing the efficiency and performance of excavation and earthmoving equipment. In 2025, as advancements in technology and materials continue to evolve, selecting the most suitable bucket teeth remains a fundamental aspect for operators and engineers in the construction and mining industries. The right bucket teeth not only enhance the digging capability but also optimize fuel consumption and extend the service life of the equipment.

Understanding the different types and applications of bucket teeth is essential for making informed decisions. With various shapes, sizes, and materials available, each type of bucket tooth is designed to perform specific tasks under varying conditions. From heavy-duty rock excavation to softer soil digging, selecting the appropriate bucket teeth can significantly impact productivity and efficiency.

As we navigate the complexities of these options in 2025, it’s important to consider factors such as terrain, material type, and machine compatibility. By adhering to best practices when choosing bucket teeth, operators can ensure that they are not only investing in the right tools but also enhancing their operational capabilities, ultimately leading to more successful project outcomes.

Bucket teeth are crucial components in earthmoving and mining operations, designed to enhance the effectiveness and efficiency of excavators and loaders. Their primary role is to penetrate and loosen soil or other materials, allowing for smoother excavation. According to a report by the International Construction and Mining Equipment Industry, properly designed bucket teeth can improve productivity by up to 30%, significantly impacting project timelines and costs.

The functionality of bucket teeth extends beyond simple excavation; they also contribute to the overall wear and tear of the bucket itself. Effective bucket teeth are typically made from high-strength steel and designed to withstand harsh conditions, thus reducing the frequency of replacements and maintenance. Data from a recent market analysis indicates that high-quality bucket teeth can lead to a 20% reduction in operating costs due to increased efficiency and longevity, making them a vital consideration for project managers and operators alike.

Understanding the various types of bucket teeth available and their specific applications is essential for maximizing machinery performance. Different materials and designs, such as pointed, flat, or serrated options, cater to specific tasks ranging from soft earth to rocky terrain. A well-informed choice based on project requirements can dramatically enhance operational efficiency while minimizing downtime.

| Type of Bucket Tooth | Material | Application | Durability Rating | Weight |

|---|---|---|---|---|

| Standard Bucket Tooth | Carbon Steel | Excavation | Medium | 25 kg |

| Extreme Duty Tooth | High Alloy Steel | Heavy Mining | High | 30 kg |

| Rock Bucket Tooth | Chrome-Molybdenum Steel | Rock Excavation | Very High | 28 kg |

| V-Shape Tooth | Bimetallic | Fine Grading | Medium | 22 kg |

| Heavy Duty Tooth | Carbon Steel | Construction | High | 24 kg |

When it comes to selecting the right bucket teeth, understanding the various types available and their specific applications is crucial for maximizing efficiency on construction and mining sites. The primary types of bucket teeth include standard, heavy-duty, and wear-resistant variants, each designed for different operational conditions. According to the latest industry reports, over 60% of excavating projects benefit significantly from customized bucket teeth that align with their particular soil or rock types, enhancing both productivity and equipment longevity.

In addition to selecting the best type, it’s essential to consider the material composition. High-quality steels and alloys are often used to enhance wear resistance and durability, which can lead to a lower overall cost when factoring in replacement frequency. The right choice can reportedly extend the lifespan of bucket teeth by up to 40%, thus reducing downtime and maintenance costs.

Tips:

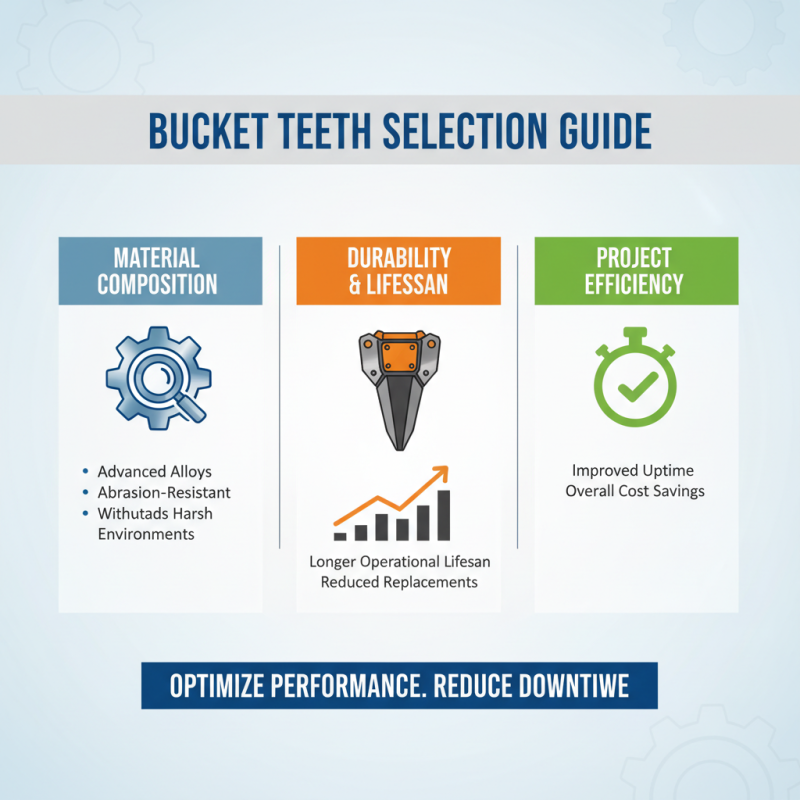

When selecting bucket teeth, a thorough understanding of the criteria involved in making the right choice is paramount. Firstly, the material composition should be considered, as it directly impacts durability and performance. High-performance bucket teeth often utilize advanced alloys designed to withstand abrasive conditions and harsh environments. This durability ensures a longer operational lifespan, reducing the need for frequent replacements, thereby improving overall efficiency in project execution.

Next, the design of the bucket teeth plays a critical role in their effectiveness. Depending on the specific application—whether it's digging in hard rock, handling loose materials, or operating in compacted soils—the shape and profile of the teeth must be tailored to meet those demands. A tooth designed for heavy-duty excavation will differ significantly from one optimized for agricultural use. Therefore, assessing the conditions in which the equipment will operate is essential for maximizing productivity and minimizing wear and tear.

Lastly, consider the compatibility of the bucket teeth with existing machinery. Ensuring that the selected teeth can be readily attached and function smoothly within the current system is crucial to avoid delays and mechanical issues. Conducting a thorough analysis of the operational requirements and matching these with the characteristics of the bucket teeth will ultimately lead to improved performance and cost-effectiveness in various applications.

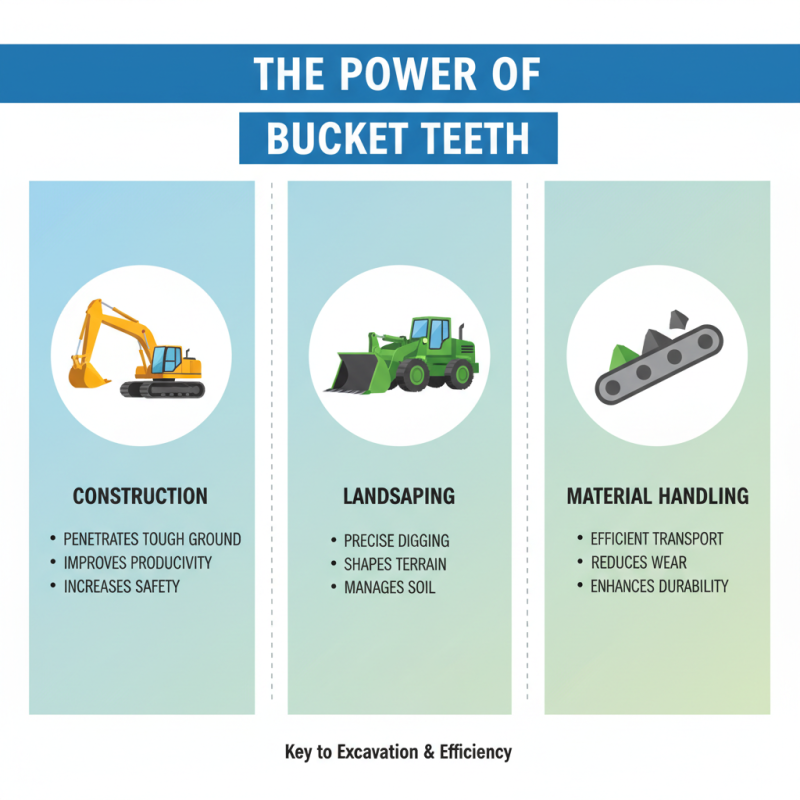

Bucket teeth play a crucial role across various industries, enhancing efficiency and durability in excavation and material handling operations. In construction, heavy machinery like excavators and loaders rely on reliable bucket teeth to penetrate tough substrates. The correct type of bucket tooth can significantly impact productivity, helping workers complete tasks more safely and swiftly. For landscaping applications, specialized bucket teeth provide precise digging capabilities, making it easier to shape terrain and manage soil.

In mining and quarrying, the application of bucket teeth is stringent due to the extreme conditions. Robust and wear-resistant teeth are essential for breaking through hardened materials while minimizing wear on machinery. This ensures longer operating life and reduced maintenance costs. Additionally, in agricultural applications, bucket teeth aid in soil preparation and crop management, optimizing the efficiency of farming equipment.

Tip: When selecting bucket teeth, consider the specific application and material type you'll be working with. Matching teeth to the hardness and composition of the material can significantly enhance performance and longevity.

Tip: Regular maintenance and inspections are vital. Checking for wear and replacing teeth as needed can prevent more extensive equipment damage and ensure consistent operational efficiency.

As we move into 2025, the landscape of bucket tooth design is evolving rapidly, driven by advancements in materials and manufacturing technologies. Industry research indicates a projected growth in the construction and mining sectors, leading to a heightened demand for more specialized bucket teeth that can withstand extreme conditions while enhancing operational efficiency. Innovations such as anti-wear coatings and lightweight composites are becoming increasingly critical, enabling operators to select parts that are not only durable but also improve fuel efficiency.

One notable trend is the integration of smart technology into bucket tooth designs. Sensors embedded in the teeth can provide real-time data on wear and performance, allowing for predictive maintenance and reducing downtime. According to a report by the Global Construction Equipment Market, implementing these technologies can lead to a reduction in equipment maintenance costs by as much as 20%. The shift towards sustainability is also driving the development of eco-friendly materials and manufacturing processes that minimize environmental impact while maintaining strength and reliability.

Tips: When choosing bucket teeth for your applications in 2025, consider the specific environmental conditions they will face. Look for innovative designs that offer enhanced wear resistance and check for compatibility with existing equipment to ensure seamless integration. Additionally, embrace the potential of smart technologies to optimize performance and streamline maintenance schedules. By staying informed on these advancements, you can make educated decisions that drive efficiency and productivity in your operations.