+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

When embarking on a construction or demolition project, selecting the right tools can significantly affect efficiency and results. Among these tools, the Breaking Hammer stands out as a crucial implement for tasks that require heavy-duty striking power. According to a report by the International Tool Manufacturers Association, approximately 30% of all construction accidents are related to improperly chosen tools, highlighting the importance of informed decision-making in tool selection. Utilizing a Breaking Hammer that fits the specific requirements of a project not only enhances productivity but also minimizes workplace injuries.

The versatility of Breaking Hammers in various applications, including concrete breaking and rock demolition, further emphasizes their importance in the toolkit of contractors and DIY enthusiasts alike. The global market for construction tools, including Breaking Hammers, is projected to reach $40 billion by 2027, driven by increasing urbanization and infrastructure development. Understanding the characteristics and specifications of Breaking Hammers, such as weight, material type, and striking capability, is essential for optimizing performance. As professionals and hobbyists look to make informed purchases, knowing how to choose the best Breaking Hammer will ensure effective and safe completion of their next project.

When undertaking major construction or demolition tasks, selecting the right type of breaking hammer is crucial to achieving efficiency and effectiveness in your project. Breaking hammers, also known as demolition hammers, come in various types, each designed for specific applications. The primary categories include electric, pneumatic, and hydraulic breaking hammers. According to industry analyses, electric breaking hammers are popular for residential and light commercial work due to their ease of use and lower noise levels, while pneumatic options are favored in larger-scale operations for their power and speed.

Electric breaking hammers typically provide impact energy ranging from 5 to 12 joules, making them suitable for lighter materials such as brick and soft concrete. Conversely, pneumatic breaking hammers can deliver impact energy upwards of 20 joules, enabling the demolition of tougher substrates, including reinforced concrete. A report from the Global Demolition Equipment Market suggests that electric hammers will see growth rates of up to 7% annually, driven by advances in technology that enhance their durability and efficiency. In contrast, pneumatic hammers remain a top choice for heavy-duty applications, highlighting the importance of understanding the intended use before making a purchase. By matching the hammer type with your project's requirements, you can ensure optimal performance and minimize excess labor time on-site.

When selecting the best breaking hammer for your project, several key features should be at the forefront of your decision-making process. First and foremost, consider the weight of the hammer. Heavier hammers are typically more effective at breaking through tough materials, but they can also lead to fatigue during extended use. Therefore, striking a balance between weight and user comfort is essential. A hammer that is too heavy may discourage productivity, while one that is too light may not deliver the necessary force.

Another important feature to look for is the vibration control mechanism. Prolonged use of heavy tools can lead to hand-arm vibration syndrome, so opting for a breaking hammer with built-in vibration dampening will enhance user comfort and safety. Additionally, take note of the hammer's handle design; ergonomic handles can significantly improve grip and reduce the risk of slippage, allowing for more precise and controlled strikes. Finally, assess the durability of the hammer materials, as a robust construction can withstand rigorous demands and extend the tool's lifespan, making it a worthwhile investment for future projects.

| Feature | Description | Importance | Recommendation |

|---|---|---|---|

| Weight | Typically ranges from 10 to 30 pounds, heavier models break harder materials more effectively. | High | Choose based on your physical strength and the material to be broken. |

| Handle Material | Common materials include fiberglass, wood, and steel, affecting durability and vibration absorption. | Medium | Fiberglass is often preferred for shock absorption. |

| Tip Style | Flat, pointed, or chisel tips are designed for specific breaking applications. | High | Select a style that matches your project's requirements. |

| Vibration Control | Some models offer features to reduce user fatigue during extended use. | Medium | Consider models with anti-vibration technology for prolonged tasks. |

| Safety Features | Check for features like safety grips and protective casings. | High | Look for tools with enhanced safety features to prevent accidents. |

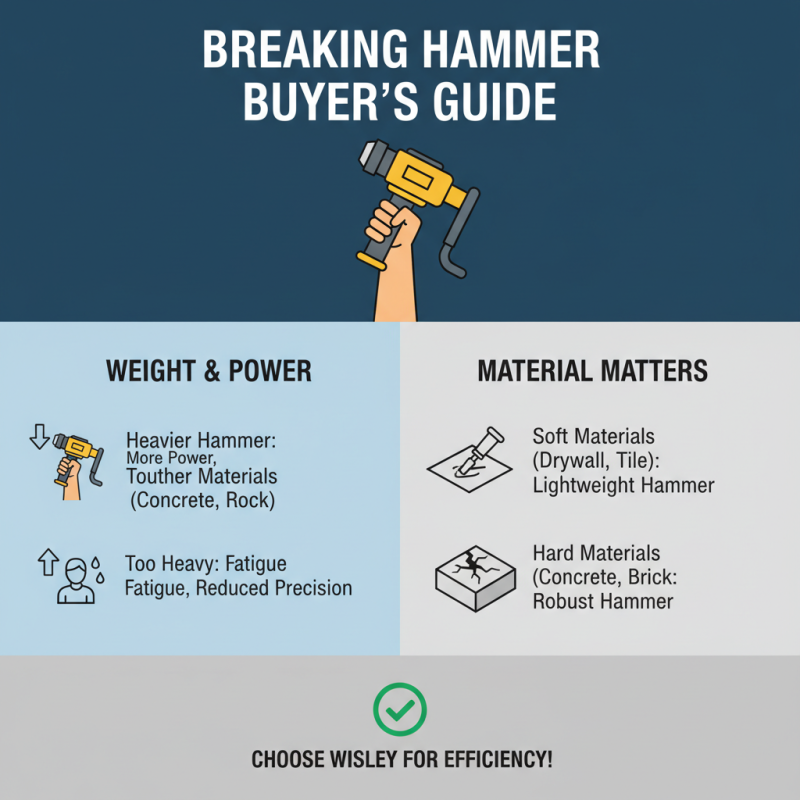

When choosing a breaking hammer for your next project, understanding the weight and power needs is crucial to ensure efficiency and effectiveness. The weight of a breaking hammer directly impacts its performance—heavier hammers generally deliver more power and break through tougher materials with greater ease. However, if the weight exceeds what you can handle comfortably, it may lead to fatigue and reduced precision. It's essential to assess the nature of the material you're working with; for instance, a lightweight hammer may suffice for softer substrates, while harder materials like concrete may require a more robust option.

Additionally, evaluating the power requirements involves considering the frequency and intensity of use. If the project demands continuous heavy-duty breaking, opting for a hammer with a higher energy output will facilitate smoother operation and minimize the time spent on the task. Conversely, for less demanding jobs, a moderate power level will likely suffice. Balancing these factors—weight versus power—will greatly influence not only your productivity but also the quality of your work, making it vital to choose a breaking hammer that aligns with the specific demands of your project.

When choosing a breaking hammer for your project, evaluating the material quality and durability is crucial. The best breaking hammers are typically made from high-quality steel and other robust materials that can withstand repeated impacts without easily bending or breaking. Look for hammers that feature hardened steel heads, as they provide strength and longevity. Additionally, consider hammers with replaceable tips, as this can extend the tool's life and ensure optimal performance over time.

Durability does not solely depend on the hammer's construction; it also involves the handle design and material. A well-designed handle made from fibreglass or other shock-absorbing materials can significantly reduce user fatigue and improve control during use. Furthermore, a non-slip grip is essential for safety, allowing for better handling even in slippery conditions. Ultimately, investing in a breaking hammer with high-quality materials will result in a tool that can endure the rigors of tough jobs, ensuring effective and efficient performance for future projects.

When utilizing a breaking hammer, understanding proper usage and maintenance is crucial to ensuring efficiency and safety on your project. According to industry reports, improper use of these tools accounts for approximately 25% of on-site accidents, leading to injuries and work delays. To maximize effectiveness, users should always adhere to the manufacturer's guidelines. Before starting any project, ensure that the hammer is correctly configured for the specific material being addressed—be it concrete, rock, or asphalt. The right chisel tip and appropriate force settings can significantly enhance performance and extend the lifespan of the tool.

In addition to proper usage, regular maintenance is vital. A study from the Construction Equipment Maintenance Association highlights that routine checks can reduce tool breakdowns by up to 30%. Users should inspect the hammer for wear and tear, focusing on the chisel tip and electrical components if applicable. Lubricating moving parts and checking for loose connections should be part of a weekly maintenance routine.

Furthermore, storing the breaking hammer in a dry and secure location when not in use will prevent rust and damage, ensuring it remains in optimal working condition for the next project. By prioritizing correct usage and diligent maintenance, users can enhance both safety and productivity on any job site.